Preparation and carbon sequestration properties of supercritical CO2 foamed concrete

-

摘要:

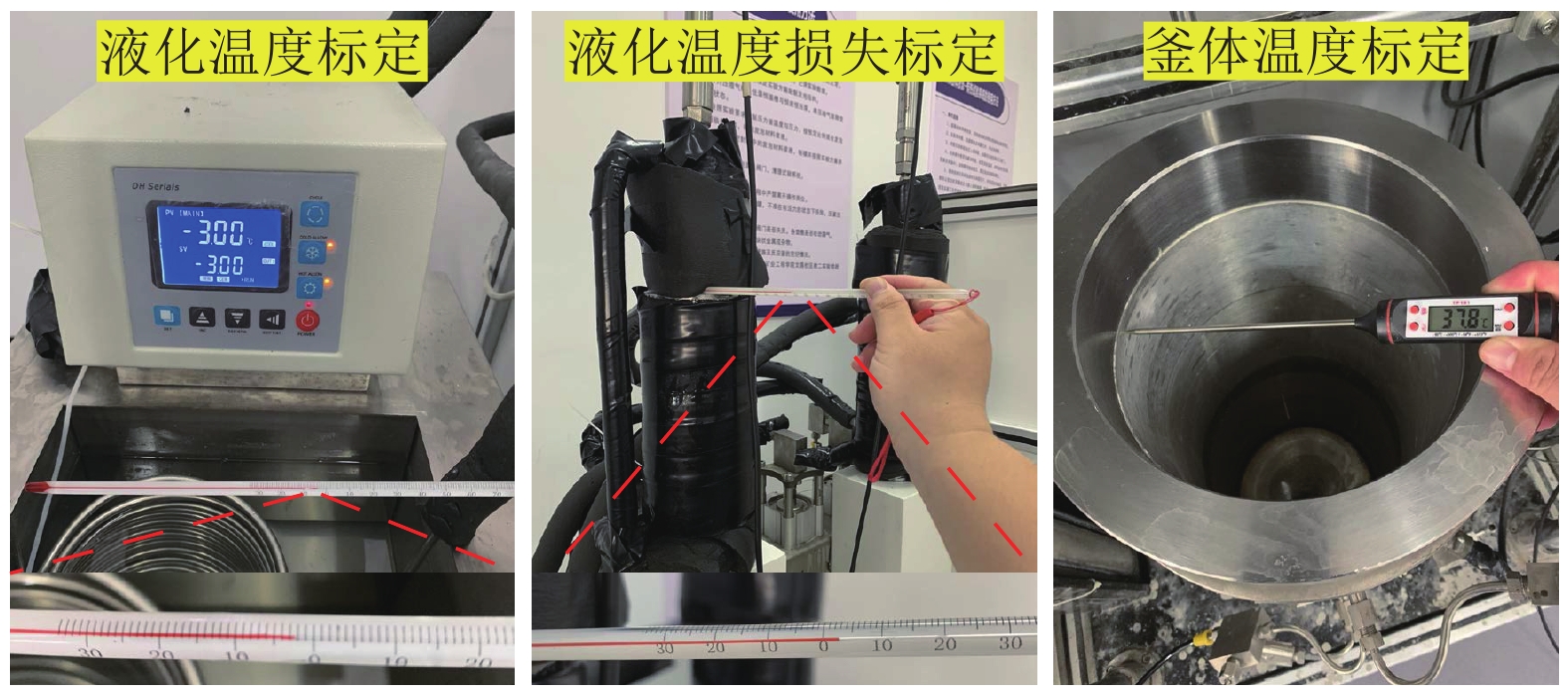

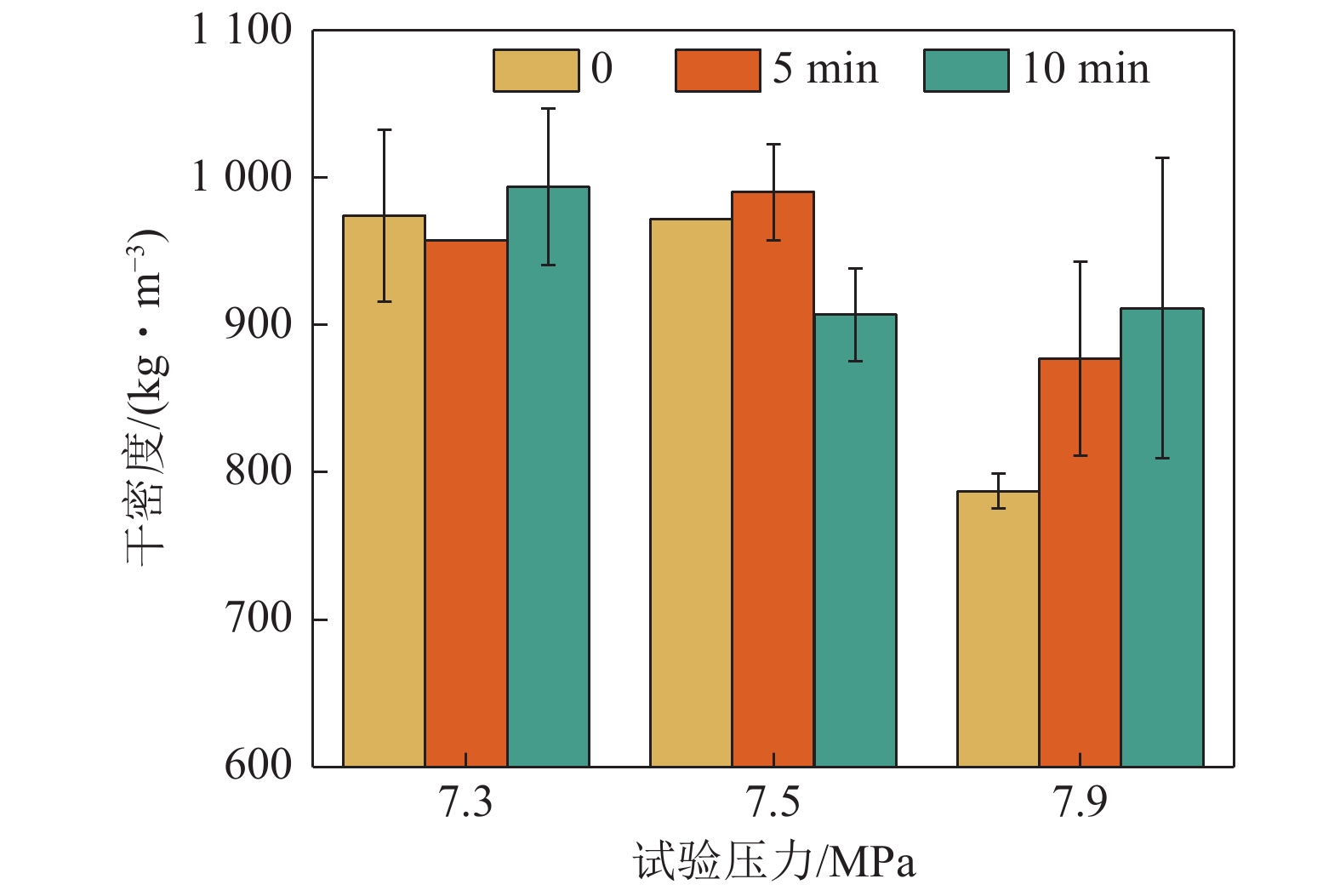

实现绿色低碳是推动煤炭产业高质量发展的必然选择。为了实现这一目标,提出一种采用超临界CO2相变发泡技术制备泡沫混凝土的方法,制备了一种兼具高孔隙结构和固碳能力的硅酸盐水泥基超临界CO2发泡混凝土。研究了超临界CO2对材料干密度、孔隙结构和固碳能力的影响规律及作用机制。结果表明:超临界CO2相变发泡混凝土制备过程是考虑硅酸盐水泥特性及其与CO2矿化反应特性的温压动态协调过程。利用超临界CO2相变发泡技术制备硅酸盐水泥基泡沫混凝土机理可分为CO2−水泥浆液共存、CO2−水泥浆液共溶、超临界CO2−水泥浆液共溶、卸压发泡4个阶段。提高实验压力可以增大超临界CO2−混凝土体系中的CO2质量分数,降低超临界CO2发泡混凝土的干密度,超临界CO2发泡混凝土干密度为787.14~993.52 kg/m3,变化范围为8.28%~19.20%。超临界CO2发泡混凝土孔隙率的发展受CO2在超临界CO2−混凝土体系中的扩散—溶解—反应行为影响,其孔隙率为47.87%~89.79%,增大实验压力,优化保压时间是制备高孔隙率超临界CO2发泡混凝土的发展方向。超临界CO2发泡混凝土泡孔总体呈均匀、规则、独立的圆孔,其孔径大致相同,约为0.2 mm。增大实验压力可以促进CO2矿化反应程度,有效优化泡孔结构及分布密度。每吨超临界CO2发泡混凝土骨架固碳率为6.32%~10.36%,泡孔储碳量为0.98~2.27 kg,具有明显的固碳潜力,但其制备工艺及参数仍需进一步改善。超临界CO2发泡混凝土有望发展为一种近零碳矿用功能性材料,对实现煤电一体化基地源头减碳意义重大。

Abstract:Realizing green and low-carbon development will be a new requirement facing the coal industry. In order to address this problem, this paper proposed a method of preparing foam concrete using a supercritical CO2 phase change foaming technology, and a Portland cement-based supercritical CO2 foamed concrete with both high pore structure and carbon sequestration capacity was prepared. The effects of supercritical CO2 on the dry density, pore structure and carbon sequestration capacity of the material and its mechanism were investigated. The experimental results revealed that the supercritical CO2 phase change foamed concrete preparation process is a temperature-pressure dynamic coordination process considering Portland cement properties and its reaction properties with CO2 mineralization. The mechanism of Portland cement-based foamed concrete prepared by the supercritical CO2 phase change foaming technology may be divided into four stages: CO2-cement slurry coexistence, CO2-cement slurry co-solution, supercritical CO2-cement slurry co-solution, and unpressurized foaming. Increasing the experimental pressure can increase the CO2 concentration in the supercritical CO2-concrete system and reduce the dry density of supercritical CO2-foamed concrete, which varies from 787.14 to 993.52 kg/m3 with a range of 8.28% to 19.20%. The development of porosity of supercritical CO2 foamed concrete was affected by the diffusion-dissolution behavior of CO2 in the supercritical CO2-concrete system, and its porosity was 47.87%−89.79%. Increasing the experimental pressure and optimizing the holding time are the development direction for preparing supercritical CO2 foamed concrete with high porosity. The supercritical CO2 foamed concrete has uniform, regular and independent circular pores with approximately the same pore diameter of 0.2 mm. Increasing the experimental pressure can promote the degree of CO2 mineralization reaction and effectively optimize the structure and distribution density of the pores. Each tonne of supercritical CO2 foamed concrete has a carbon sequestration capacity of 6.32%−10.36% in the skeleton and 0.98−2.27 kg in the pore, which has obvious carbon sequestration potential, but the preparation process and parameters still need to be further improved. The results show that the supercritical CO2 foamed concrete is expected to be developed into a functional material with near-zero-carbon for mining, which is of great significance for realizing the carbon reduction at the source of coal power integration base.

-

表 1 OPC主要组成质量分数

Table 1 Content of main compounds of OPC

% SiO2 Al2O3 Fe2O3 CaO MgO SO3 24.99 8.26 4.03 51.42 3.71 2.51 表 2 超临界CO2发泡混凝土配比

Table 2 Proportioning of supercritical CO2 foamed concrete

水泥质量/g 水质量/g 发泡液原料质量/g 水灰比 AC-1202 HPMC 水 3 000 1 500 3 6 1500 0.5 表 3 超临界CO2发泡混凝土实验方案

Table 3 Experimental plan for supercritical CO2 foamed concrete

方案 实验压力/MPa 保压时间/min 7.3-0 7.3 0 7.3-5 5 7.3-10 10 7.5-0 7.5 0 7.5-5 5 7.5-10 10 7.9-0 7.9 0 7.9-5 5 7.9-10 10 -

[1] 谢和平,张吉雄,高峰,等. 煤矿负碳高效充填开采理论与技术构想[J]. 煤炭学报,2024,49(1):36−46. XIE Heping, ZHANG Jixiong, GAO Feng, et al. Theory and technical conception of carbon negative and efficient backfill mining in coal mines[J]. Journal of China Coal Society,2024,49(1):36−46.

[2] 刘浪,方治余,王双明,等. 煤矿充填固碳理论基础与技术构想[J]. 煤炭科学技术,2024,52(2):292−308. doi: 10.12438/cst.2023-1485 LIU Lang, FANG Zhiyu, WANG Shuangming, et al. Theoretical basis and technical of carbon dioxide backfill in coal Mine[J]. Coal Science and Technology,2024,52(2):292−308. doi: 10.12438/cst.2023-1485

[3] 谢和平,高明忠,刘见中,等. 煤矿地下空间容量估算及开发利用研究[J]. 煤炭学报,2018,43(6):1484−1503. XIE Heping, GAO Mingzhong, LIU Jianzhong, et al. Research on exploitation and volume estimation of underground space in coal mines[J]. Journal of China Coal Society,2018,43(6):1484−1503.

[4] 黄浩,王涛,方梦祥. 二氧化碳矿化养护混凝土技术及新型材料研究进展[J]. 化工进展,2019,38(10):4363−4373. HUANG Hao, WANG Tao, FANG Mengxiang. Review on carbon dioxide mineral carbonation curing technology of concrete and novel material development[J]. Chemical Industry and Engineering Progress,2019,38(10):4363−4373.

[5] 史才军,王吉云,涂贞军,等. CO2养护混凝土技术研究进展[J]. 材料导报,2017,31(5):134−138. doi: 10.11896/j.issn.1005-023X.2017.05.022 SHI Caijun, WANG Jiyun, TU Zhenjun, et al. Progresses in CO2 curing of concrete[J]. Mateials Reports,2017,31(5):134−138. doi: 10.11896/j.issn.1005-023X.2017.05.022

[6] 涂贞军,史才军,何平平,等. 掺CaCO3粉及后续水养护对CO2养护混凝土强度和显微结构的影响[J]. 硅酸盐学报,2016,44(8):1110−1119. TU Zhenjun, SHI Caijun, HE Pingping, et al. Effects of CaCO3 powder and subsequent water curing on compressive strength and microstructure of CO2-cured concrete[J]. Journal of the Chinese Ceramic Society,2016,44(8):1110−1119.

[7] GAO H, LIAO H, WANG M, et al. Reinforcing the physicochemical properties of concrete through synergism of CO2 curing and Ca(OH)2 solution drenching[J]. Construction and Building Materials,2021,280:122546. doi: 10.1016/j.conbuildmat.2021.122546

[8] SONG B, SHI C, HU X, et al. Effect of early CO2 curing on the chloride transport and binding behaviors of fly ash-blended Portland cement[J]. Construction and Building Materials,2021,288:123113. doi: 10.1016/j.conbuildmat.2021.123113

[9] FANG Z, LIU L, ZHANG X, et al. Carbonation curing of modified magnesium-coal based solid waste backfill material for CO2 sequestration[J]. Process Safety and Environmental Protection,2023,180:778−788. doi: 10.1016/j.psep.2023.10.049

[10] 王双明,刘浪,朱梦博,等. “双碳”目标下煤炭绿色低碳发展新思路[J]. 煤炭学报,2024,49(1):152−171. WANG Shuangming, LIU Lang, ZHU Mengbo, et al. New way for green and low-carbon development of coal under the target of “double carbon”[J]. Journal of China Coal Society,2024,49(1):152−171.

[11] 桑树勋,袁亮,刘世奇,等. 碳中和地质技术及其煤炭低碳化应用前瞻[J]. 煤炭学报,2022,47(4):1430−1451. SANG Shuxun, YUAN Liang, LIU Shiqi, et al. Geological technology for carbon neutrality and its application prospect for low carbon coal exploitation and utiliation[J]. Journal of China Coal Society,2022,47(4):1430−1451.

[12] 卞正富,伍小杰,周跃进,等. 煤炭零碳开采技术[J]. 煤炭学报,2023,48(7):2613−2625. BIAN Zhengfu, WU Xiaojie, ZHOU Yuejin, et al. Coal mining technology with net zero carbon emission[J]. Journal of China Coal Society,2023,48(7):2613−2625.

[13] NGO I, MA L, ZHAI J, et al. Enhancing fly ash utilization in backfill materials treated with CO2 carbonation under ambient conditions[J]. International Journal of Mining Science and Technology,2023,33(3):323−337. doi: 10.1016/j.ijmst.2023.02.001

[14] 马立强,翟江涛,ICHHUY N. CO2矿化煤基固废制备保水开采负碳充填材料试验研究[J]. 煤炭学报,2022,47(12):4228−4236. MA Liqiang, ZHAI Jiangtao, ICHHUY N. Experimental study on preparation of negative carbon filling material for water protection mining by CO2 mineralization of coal-based solid waste[J]. Journal of China Coal Society,2022,47(12):4228−4236.

[15] 李磊,潘鑫,刘鲁豫. 工业固废CO2矿化协同减污降碳关键技术进展[J]. 洁净煤技术,2024,30(7):1−12. LI Lei, PAN Xin, LIU Luyu. Advances in key technologies of synergistic pollution and carbon reduction by industrial solid waste CO2 mineralization[J]. Clean Coal Technology, 2024, 30(7):1−12.

[16] 他旭鹏,张源,万志军,等. 硅酸盐水泥基CO2泡沫混凝土的制备及机理[J]. 煤炭学报,2023,48(S2):757−765. TA Xupeng, ZHANG Yuan, WAN Zhijun, et al. Preparation and mechanism of Portland cement-based CO2 foam concrete[J]. Journal of China Coal Society,2023,48(S2):757−765.

[17] TA X, ZHANG Y, WAN Z, et al. Study on Preparation and performance of CO2 foamed concrete for heat insulation and carbon storage[J]. Materials,2023,16(7):2725. doi: 10.3390/ma16072725

[18] TA X, WAN Z, ZHANG Y, et al. Effect of carbonation and foam content on CO2 foamed concrete behavior[J]. Journal of Materials Research and Technology,2023,23:6014−6022. doi: 10.1016/j.jmrt.2023.02.178

[19] SNÆBJÖRNSDÓTTIR S Ó, SIGFÚSSON B, MARIENI C, et al. Carbon dioxide storage through mineral carbonation[J]. Nature Reviews Earth & Environment,2020,1(2):90−102.

[20] SIM S R, RYU D W. Effect of the concrete slurry waste ratio on supercritical CO2 sequestration[J]. Materials,2023,16(2):742. doi: 10.3390/ma16020742

[21] PARK S, MOON H, KIM J H, et al. Reaction of hydrated cement paste with supercritical carbon dioxide[J]. Construction and Building Materials,2021,281:122615. doi: 10.1016/j.conbuildmat.2021.122615

[22] 董桂伟,赵国群,丁汪洋,等. 基于多阶压力控制的双峰泡孔聚合物发泡行为及性能[J]. 材料导报,2022,36(2):209−213. DONG Guiwei, ZHAO Guoqun, DING Wangyang, et al. Foaming behavior and properties of bimodal cellular polymer based on multi-step pressure control[J]. Materials Reports,2022,36(2):209−213.

[23] 文华银,张文焕,贺婉,等. 超临界CO2制备三元乙丙橡胶微孔泡沫[J]. 材料导报,2021,35(2):2166−2170. WEN Huayin, ZHANG Wenhuan, HE Wan, et al. Preparation of microcellular EPDM foams by supercritical CO2[J]. Materials Reports,2021,35(2):2166−2170.

[24] WANG D, NOGUCHI T, NOZAKI T. Increasing efficiency of carbon dioxide sequestration through high temperature carbonation of cement-based materials[J]. Journal of Cleaner Production,2019,238:117980. doi: 10.1016/j.jclepro.2019.117980

[25] SHI X, ZHANG G, LIU Y, et al. Microcellular foaming of polylactide and poly(butylene adipate-co-terphathalate) blends and their CaCO3 reinforced nanocomposites using supercritical carbon dioxide[J]. Polymers for Advanced Technologies,2016,27(4):550−560. doi: 10.1002/pat.3768

[26] MA C, CHEN B. Experimental study on the preparation and properties of a novel foamed concrete based on magnesium phosphate cement[J]. Construction and Building Materials,2017,137:160−168. doi: 10.1016/j.conbuildmat.2017.01.092

[27] LI J, ZHANG G, SHANG Z, et al. Enhanced electromagnetic interference shielding and mechanical properties of foamed epoxy nanocomposites containing carbon nanofiber treated with silicone surfactant[J]. Journal of Applied Polymer Science,2018,135(43):46833. doi: 10.1002/app.46833

[28] COLTON J S, SUH N P. The nucleation of microcellular thermoplastic foam with additives:Part I:theoretical considerations[J]. Polymer Engineering & Science,1987,27(7):485−492.

[29] 史志远. 典型通用聚合物多相体系的超临界CO2发泡行为及性能调控[D]. 合肥:中国科学技术大学,2022. SHI Zhiyuan. Supercritical CO2 foaming behavior and property regulation of typical general polymer multiphase system[D]. Hefei:University of Science and Technology of China, 2022.

[30] 郑晓平. 利用超临界CO2制备聚碳酸酯微孔泡沫及其性能研究[D]. 宁波:宁波大学,2019. ZHEN Xiaoping. Preparation of polycarbonate foams by supercritical carbon dioxide and study on its property[D]. Ningbo:Ningbo University, 2019.

[31] HUANG P, WU F, PANG Y, et al. Enhanced dispersion, flame retardancy and mechanical properties of polypropylene/intumescent flame retardant composites via supercritical CO2 foaming followed by defoaming[J]. Composites Science and Technology,2019,171:282−290. doi: 10.1016/j.compscitech.2018.12.029

[32] LIAO R, YU W, ZHOU C. Rheological control in foaming polymeric materials:I. Amorphous polymers[J]. Polymer,2010,51(2):568−580. doi: 10.1016/j.polymer.2009.11.063

[33] KABALAH-AMITAI L, MAYZEL B, KAUFFMANN Y, et al. Vaterite crystals contain two interspersed crystal structures[J]. Science,2013,340(6131):454−457. doi: 10.1126/science.1232139

[34] BINEVSKI P V, BALABUSHEVICH N G, UVAROVA V I, et al. Bio-friendly encapsulation of superoxide dismutase into vaterite CaCO3 crystals. Enzyme activity, release mechanism, and perspectives for ophthalmology[J]. Colloids and Surfaces B:Biointerfaces,2019,181:437−449. doi: 10.1016/j.colsurfb.2019.05.077

[35] 张源,他旭鹏,覃述兵,等. CO2泡沫混凝土碳封存潜力分析[J]. 环境科学,2023,44(9):5308−5315. ZHANG Yuan, TA Xupeng, QIN Shubing, et al. Analysis of carbon storage potential of CO2 foamed concrete[J]. Environmental Science,2023,44(9):5308−5315.

下载:

下载: