移动阅读

施龙青1,曲兴玥1,韩 进2,邱 梅1,高卫富3,秦道霞4,刘海松5,6

(1.山东科技大学 地球科学与工程学院,山东 青岛 266590; 2.山东科技大学 信息科学与工程学院,山东 青岛 266590; 3.山东科技大学 资源与土木工程系,山东 泰安 271109; 4.肥城矿业集团 单县能源有限公司,山东 菏泽 274300; 5.青岛地矿岩土工程有限公司,山东 青岛 266100; 6.青岛地质工程勘察院,山东 青岛 266100)

摘 要:在我国华北型石炭—二叠系煤田中,煤层底板灰岩岩溶突水现象尤为突出。为准确地评价煤层底板灰岩岩溶突水危险性,防治煤矿水害事故,实现承压水体上煤层安全开采。基于未知测度-集对分析理论,选用含水层厚度、单位涌水量、充水含水层渗透性、水压、断层影响因子、含水层厚度、含水层岩性组合特征以及底板破坏深度8个指标评价煤层底板灰岩岩溶突水危险性。采用有序二元比较量化法和区间数模糊决策矩阵EA-TOPSIS排序模型分别确定煤层底板灰岩岩溶突水主控因素权重。在此基础之上,基于冲突证据理论将二者进行耦合,得到煤层底板灰岩岩溶突水主控因素组合权重,保证了对动态模型指标相对重要性的有效评价。基于未知测度-集对分析理论,构建单指标直线型未知测度函数及非直线型未知测度函数,并以新汶煤田煤层开采为例,将30个监测点处实测的8个指标值代入,建立多指标综合测度矩阵。引入“置信度”评价准则判定样本数据Xi所属的危险性等级。并通过集对分析,进一步表征新汶煤田煤层开采过程中煤层底板灰岩岩溶突水风险总体态势。研究表明,评价结果与矿山实际情况相吻合。在此基础之上,依据搜集的大量华北煤矿突水案例,以其中典型的15个为例,将建立的模型推广到整个华北煤田底板突水危险性的评价。通过与矿井实际突水情况对比可以发现,模型确定的矿井突水危险性等级与实际相吻合,表明该模型对于评价整个华北煤田底板灰岩岩溶突水危险性具有一定的适宜性。

关键词:底板灰岩岩溶突水;危险性评价;有序二元比较量化;EA-TOPSIS;冲突证据理论;未知测度评价;集对分析

施龙青,曲兴玥,韩进,等.多模型融合评价煤层底板灰岩岩溶突水危险性[J].煤炭学报,2019,44(8):2484-2493.doi:10.13225/j.cnki.jccs.KJ19.9508

SHI Longqing,QU Xingyue,HAN Jin,et al.Multi-model fusion for assessing the risk of inrush of limestone karst water through mine floor[J].Journal of China Coal Society,2019,44(8):2484-2493.doi:10.13225/j.cnki.jccs.KJ19.9508

中图分类号:TD745

文献标志码:A

文章编号:0253-9993(2019)08-2484-10

收稿日期:2019-04-22

修回日期:2019-05-20

责任编辑:郭晓炜

基金项目:国家自然科学基金资助项目(41572244,41807283,51804184)

作者简介:施龙青(1964—),男,江苏扬州人,教授,博士生导师。E-mail:cattony2002@163.com

通讯作者:韩 进(1968—),女,山东章丘人,教授。E-mail:shnk123@163.com

SHI Longqing1,QU Xingyue1,HAN Jin2,QIU Mei1,GAO Weifu3,QIN Daoxia4,LIU Haisong5,6

(1.College of Earth Sciences&Engineering,Shandong University of Science and Technology,Qingdao266590,China; 2.College of Computer Science and Engineering,Shandong University of Science and Technology,Qingdao266590,China; 3.Department of Resource and Civil Engineering,Shandong University of Science and Technology,Taian271109,China; 4.Shanxian Energy Co.,Ltd.,Feicheng Mining Group,Heze274300,China; 5.Qingdao Geological,Mineral and Geotechnical Engineering Co.,Ltd.,Qingdao266100,China; 6.Qingdao Geo-Engineering SurveringInstteitu,Qingdao266100,China)

Abstract:Inrush of limestone karst water through mine floor occurs frequently in the Carboniferous-Permian coalfield in northern China.How to accurately evaluate the risk of inrush of limestone karst water through mine floor has guiding significance for preventing and controlling water disaster accidents in coal mines and realizing the safe mining of coal seams above confined water bodies.The unascertained measurement evaluation and set pair analysis method were proposed to evaluate water inrushes using eight indices:aquifer thickness,unit water inflow,permeability of aquifers,water pressure,fault influencing factors,aquiclude thickness,aquiclude lithologic assemblage characteristics and destroyed floor depth.Ordered binary comparison quantization method and interval number fuzzy decision matrix of EA-TOPSIS ordering were used to obtain weights for these eight factors.Conflicting evidence theory was then applied to couple these weights calculated by ordered binary comparison quantization and EA-TOPSIS ordering,ensuring the effective evaluation of the relative importance of each indicator for the dynamic model.Ultimately,the unascertained measurement evaluation and set pair analysis method were utilized to evaluate the risk of limestone karst water inrush from coal seam floor.Based on the type of index value,the state classification was carried out through quantitative analysis,and single index measure functions,including linear and non-linear patterns,were constructed.Then,eight indicator values,collected at 30 monitoring sites in Xinwen coalfield for evaluating the risk of water inrush from coal seam floor,were substituted into the measure functions to determine the multi-index comprehensive measurement matrix.Credible degree recognition criterion was then introduced to determine the risk level of the sample dataXi.Furthermore,the general situation of risk of water inrush from coal seam floor during coal seam mining in Xinwen coalfield was presented by means of set pair potential analysis.The research shows that the evaluation results are consistent with the actual situation of the mine.On this basis,according to a large number of water inrush cases collected in north China-type coal mines,taking 15 typical cases as examples,the established model was applied to the risk assessment of floor water inrush for the whole north China-type coal mines.By comparing with the actual water inrush data,it can be found that the hazard degree of mine water inrush determined by the model is consistent with the actual situation,which indicates that the model has certain suitability for evaluating the risk of karst water inrush from floor limestone in the whole north China-type coalfield.

Key words:inrush of limestone karst water through mine floor;risk assessment;ordered binary comparison quantization;EA-TOPSIS;conflicting evidence theory;unascertained measurement evaluation;set pair analysis

我国煤田经过近一个世纪的煤炭开采,多数煤层的开采已进入深层位,特别是华北型煤田,大部分矿井已开采石炭系下部煤层,石炭世煤层距奥陶系灰岩较近,在构造作用下,底板灰岩岩溶往往和奥陶系灰岩构成统一的水力系统,煤矿受岩溶水威胁尤为突出[1-3]。如1984年6月,开滦矿务局范各庄煤矿奥灰岩溶陷落柱突水,最大突水量达123 200 m3/h,死亡11人,直接经济损失4.95亿元;1993-01-05,肥城矿务局国家庄煤矿-210 m水平北大巷发生灰岩突水,最大突水量为32 970 m3/h,直接经济损失1.35亿元;2010-03-01—07-29,神华乌海能源公司骆驼山煤矿16号煤矿+870 m水平回风大巷掘进工作面底板灰岩突水,瞬时最大出水量为72 000 m3/h,造成32人死亡[4-5]。因此,如何准确地评价煤层底板灰岩岩溶突水危险性对于防治煤矿水害事故,实现承压水体上煤层安全开采具有重要指导意义[6]。

目前,用于评价煤层底板灰岩岩溶突水危险性的方法主要有GIS脆弱性指数法[7]、模糊综合评判法[8]、最小二乘支持向量机法[9]、模糊层次分析法[10]、Fisher判别法[11]等。但要保证这些方法评价的准确性,必须满足其适用条件或提供可靠的参数,而现场地质及水文地质资料很难满足这种要求,因此这些方法往往难以推广。笔者结合华北煤田煤层底板灰岩岩溶突水实例,基于有序二元比较量化法、区间数模糊决策矩阵EA-TOPSIS排序和冲突证据理论,提出了一种将单指标未知测度理论与集对分析相结合的方法来评价煤层底板灰岩岩溶突水风险,并将其应用于新汶煤田,最终推广到整个华北煤田底板突水危险性的评价。研究表明,评价结果与矿山实际情况相吻合,具有较高的准确性,克服了主控因素间量纲不一的技术难题,为矿井水害防治提供了理论依据。

新汶煤田是山东省境内主要的煤炭生产基地,属于石炭—二叠系华北型含煤地层,由老到新发育有为奥陶系(O)、石炭系(C)、二叠系(P)、第三系(R)和第四纪(Q)地层。井田内共含煤18层,其中可采煤层6层(2,4,6,11,13,15煤层),可采煤层平均总厚9.41 m,占煤系含煤总厚的74%。新汶煤田地质构造特征在区域构造上为鲁西构造所控制,在区域上处于莲花山断裂和羊流断裂构成的地堑盆地内,煤田内的断层明显受到上述两条断裂控制,新汶煤田构造如图1所示。

煤层底板灰岩岩溶突水的发生主要取决于各种因素之间复杂的非线性关系[12]。本文选取含水层厚度、单位涌水量、充水含水层渗透性、含水层水压、断层影响因子、隔水层厚度、隔水层岩性组合特征及底板破坏深度8个因素作为影响煤层底板灰岩岩溶突水主控因素。

(1)含水层厚度。

生产实践证明,影响煤层安全开采的岩溶系统主要是奥灰顶部的上马家沟组岩溶系统。利用Matlab软件绘制奥灰上马家沟组上段含水层厚度等值线专题图(图2(a))。

图1 新汶煤田构造纲要

Fig.1 Structure outline map of Xinwen coalfield

图2 主控因素等值线

Fig.2 Contour maps of main controlling factors

(2)单位涌水量。

新汶煤田内共有180个井下灰岩水文钻孔,共进行46次抽(放)水试验,利用Matlab软件绘制钻孔单位涌水量等值线专题图(图2(b))。

(3)充水含水层渗透性。

采用地面抽水试验资料计算煤层底板充水含水层渗透系数,利用Matlab软件绘制充水含水层渗透系数等值线专题图(图2(c))。

(4)含水层水压。

整个煤田范围内,煤层底板突水含水层最高水压可达7.2 MPa,利用Matlab软件绘制含水层水压等值线专题图(图2(d))。

(5)断层影响因子。

研究区范围内地质构造以断层为主,采用断层影响因子作为指标对煤田构造进行评价:

其中,E为断层影响因子;li为第i条断层落在单元内的走向长度,m;hi为第i条断层的落差,m;S为单元面积,m2;n为落在单元内的断层条数;M为构造交点和端点的归一化值。利用Matlab软件绘制断层影响因子等值线专题图(图2(e))。

(6)隔水层厚度。

研究区煤层底板灰岩岩溶突水主要发生在隔水层厚度小于40 m的范围内,利用Matlab软件绘制隔水层厚度等值线专题图(图2(f))。

(7)隔水层岩性组合特征。

研究区范围内煤层底板隔水层岩性以泥岩、粉砂岩、黏土岩为主,采用泥岩比率作为隔水层阻抗水性能的评价指标,利用Matlab软件绘制煤层底板隔水层泥岩比率等值线专题图(图2(g))。

(8)底板破坏深度。

依据《建筑物、水体、铁路及主要井巷煤柱留设与压煤开采规程》,计算突水位置矿山压力作用下的煤层底板破坏深度:

h1=0.008 5H+0.166 5α+0.107 9L-4.357 9

其中,h1为矿山压力作用下煤层底板破坏深度,m;H为开采深度,m;α为煤层倾角,(°);L为工作面斜长,m。利用Matlab软件绘制底板破坏深度等值线专题图(图2(h))。

采用三标度法对各指标重要程度进行二元对比,结合专家意见,构建8×8阶定性排序比较矩阵R,结果见表1。

表1 评价指标相对重要性

Table 1 Relative importance of evaluation indicators

依据比较矩阵R求解主控因素重要性程度排序指数zi,构造判断矩阵P:

其中, 令Q=lgP=[lg(pij)]n×n,确定判断矩阵P的反对称矩阵Q。令

令Q=lgP=[lg(pij)]n×n,确定判断矩阵P的反对称矩阵Q。令![]() 为矩阵Q中的元素量,构造矩阵G=[gij]n×n,结果见表2。

为矩阵Q中的元素量,构造矩阵G=[gij]n×n,结果见表2。

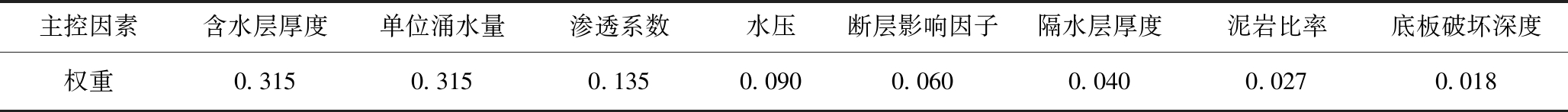

由此获得的矩阵G是判断矩阵P的拟优传递矩阵,且其完全满足一致性要求,采用和积法、方根法及串联二元比较法求解主控因素权重,见表3,4,5,最终权重:

(0.28,0.28,0.05,0.20,0.04,0.08,0.02,0.04)

新汶煤田主要突水矿井全体记为X,指标因素集合记为C,通过级差变换确定标准化区间数模糊决策矩阵见表6。

表2 重要性排序指数拟优传递矩阵

Table 2 Quasi-optimal transfer matrix of importance sorting index

表3 和积法求解主控因素权重

Table 3 Sum-product method to solve weights of main controlling factors

表4 方根法求解主控因素权重

Table 4 Square root method to solve weights of main controlling factors

表5 串联二元比较法求解主控因素权重

Table 5 Series binary comparison method to solve weights of main controlling factors

表6 标准化区间数模糊决策矩阵

Table 6 Standardized interval number fuzzy decision matrix table

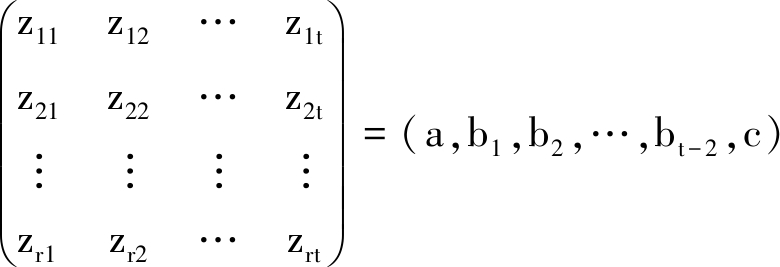

结合灰色关联度GRD及理想解法TOPSIS确定标准化区间数模糊决策均值矩阵![]() 正理想解及负理想解。计算第i个矿井突水与正、负理想解关于第j个指标的灰色关联度[13]:

正理想解及负理想解。计算第i个矿井突水与正、负理想解关于第j个指标的灰色关联度[13]:

0.593,0.516,0.608,0.629,0.611)

0.544,0.657,0.537,0.523,0.546)

其中,k为灰色关联度;μ为正负理想解。用误差传递公式计算区间数模糊决策矩阵R关于正、负理想解的指标权重向量区间形式:

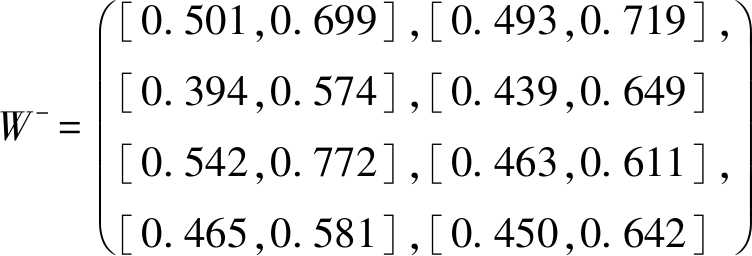

设c=[cL,cU],d=[dL,dU],记L(c)=cU-cL,L(d)=dU-dL,则a≥b的可能度p(a≥b)可表达为以下6部分[14]:

式中,c,d,L,U,L(c),L(d)为定义的区间数。

求解可能度矩阵P排序向量,计算主控因素灰色关联相对贴近度![]() 并进行标准化处理,最终得到基于区间数模糊决策矩阵EA-TOPSIS排序确定的主控因素权重:

并进行标准化处理,最终得到基于区间数模糊决策矩阵EA-TOPSIS排序确定的主控因素权重:

W2=(0.146,0.147,0.074,0.123,

0.162,0.119,0.111,0.118)

设EA-TOPSIS排序法及有序二元比较量化法确定的主控因素权重分别为w1,w2,定义不同方法求解同一指标权重的相容系数[15]:

式中,wi(ck),wj(ck)为指标权重;ui,j(ck)为相容系数。

运用MATLAB绘制相容系数图像如图3所示,从图3可以看出,利用不同方法确定同一指标权重存在一定相容性,但同时也存在一定的冲突。于是依据公式![]() 计算2种方法求解主控因素权重可信度,在此基础之上,对源权重进行分配,确定证据理论的mass函数:m1,m2,并依据D-S证据理论,对其进行融合,结果见表7,其中,Θ为不确定性。

计算2种方法求解主控因素权重可信度,在此基础之上,对源权重进行分配,确定证据理论的mass函数:m1,m2,并依据D-S证据理论,对其进行融合,结果见表7,其中,Θ为不确定性。

表7 权重融合结果

Table 7 Results of weight fusion

图3 相容系数函数图像

Fig.3 Images of compatibility coefficient function

依据表8指标分级划分确定评价等级空间阈值di,见表9,构建煤层底板灰岩岩溶突水危险性评价单指标测度函数,其中单指标直线型测度函数如图4所示,非直线型测度函数如图5所示。表8中H,q,K,p,E,M,μ,h分别为含水层厚度,单位涌水量,渗透系数,水压,断层影响因子,隔水层厚度,泥岩比率,底板破坏深度。

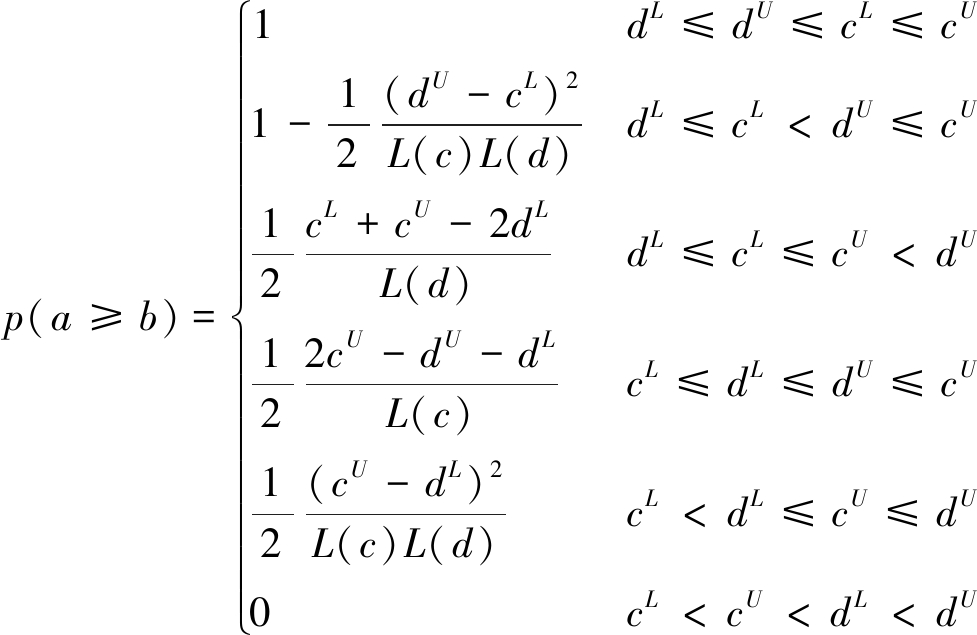

依据新汶煤田煤层底板灰岩岩溶突水危险性评价指标实测数据,按照测度函数构造比例对其进行量纲化处理,基于直线型、非直线型未知测度函数图像,求得30个样本数据的单指标直线型、非直线型未知测度评价矩阵Zlinear,Znon-linear。将冲突证据理论耦合的主控因素权重向量记为W=(W1,W2,…,Wr),则t元联系数μ的同一、差异、对立度隶属度矩阵M定义为主控因素权重向量W与单指标未知测度评价矩阵Z的乘积,表示对样本数据的多指标综合测度评价,即:

表8 指标分级划分

Table 8 Index hierarchical classification

表9 评价等级空间阈值

Table 9 Spatial threshold of evaluation grade

图4 直线型测度函数

Fig.4 Linear measure function images

图5 非直线型测度函数

Fig.5 Non-linear measure function images

M=W·(Z)r×t=(W1,W2,…,Wr)·

引入“置信度”评价准则,取置信度λ=0.6,若C1>C2>…>Cp,且![]() 则判定样本数据Xi属于第k0个评价等级Ck0,评价结果见表10,直线型测度评价与非直线型测度评价对比结果如图6所示。

则判定样本数据Xi属于第k0个评价等级Ck0,评价结果见表10,直线型测度评价与非直线型测度评价对比结果如图6所示。

图6 结果对比

Fig.6 Result comparison

以X01为样本1的底板突水点编号,以此类推,从表10,11可以看出,X01,X08,X26,X29底板突水等级为Ⅰ级,煤层开采过程中极易发生底板突水事故,分别位于孙村煤矿第4层反下山位置、良庄煤矿51302工作面、华丰煤矿2号井-90 m水平以及华丰煤矿4号井-90 m水平;X014,X015,X016底板突水等级为Ⅱ级,在煤层开采过程中也易发生底板突水事故,分别位于协庄煤矿31103E工作面、31104E工作面、31102E工作面。笔者进一步通过集对势分析呈现新汶矿区煤层开采底板突水危险性总体态势,首先定义联系数μ1的表达式系数分量F=(1,p1,p2,…,pt-2,q)T,得到直线型、非直线型联系度表达式:

μ=M·F=(a,b1,b2,…,bt-2,c)·

(1,p1,p2,…,pt-2,q)T=

a+b1p1+b2p2+…+bt-2pt-2+cq

μlinear=0.21+0.16p1+0.17p2+0.35q

μnon-linear=0.22+0.14p1+0.15p2+0.39q

依据集对势公式e(H)=a/c,得到联系数对应的集对势:

elinear=0.21/0.35=0.6

enon-linear=0.22/0.39=0.56

计算得到elinear,enon-linear均小于1,表明两者表征的突水风险态势处于反势区,存在较高的突水风险。

华北型煤田煤炭资源总量占全国总量的60%,但由于长期开采,多数矿井已进入石炭系深部煤层的开采,其多形成于滨海、潮坪、潟湖等海相环境,含煤岩系中发育厚度不一的多层碳酸盐岩,导致矿井在开采过程中面临着一定的灰岩岩溶突水危险性[16]。因而笔者搜集了大量的华北煤矿突水案例,并选取其中典型的15个为例,将本文建立的模型推广到整个华北煤田底板突水危险性的评价,结果如图7所示。通过与矿井实际突水情况对比可以发现,模型确定的矿井突水危险性等级与实际相吻合,表明该模型对于评价整个华北煤田底板灰岩岩溶突水危险性具有一定的适宜性。

表10 未知测度模型直线评价结果

Table 10 Evaluation results of the linear unascertained measure model

表11 未知测度模型非直线评价结果

Table 11 Evaluation results of the non-linear unascertained measure model

图7 华北煤田评价结果

Fig.7 Evaluation results of coalfields in North China

(1)综合考虑新汶煤田影响煤层底板灰岩岩溶突水的8项因素,基于有序二元比较量化法及区间数模糊决策矩阵EA—TOPSIS排序确定主控因素权重,并通过冲突证据理论进行耦合,保证了对动态模型中每个指标的相对重要性进行有效评估。

(2)利用单指标未知测度—集对分析数学理论建立了煤层底板灰岩岩溶突水危险性评价模型,结合新汶矿区实测数据,利用未确知测度评价模型对30个块段进行了分析,建立各评价因素的单指标测度函数,降低了主观因素的影响。然后引入可信度识别准则来确定样本数据Xi的风险水平。并通过集对分析确定新汶煤田煤层开采过程中煤层底板突水风险的总体态势,最终推广到整个华北煤田底板突水危险性的评价,研究表明,评价结果与矿山实际情况相吻合。

参考文献 :

[1] 施龙青,卜昌森,魏久传,等.华北型煤田奥灰岩溶水防治理论与技术[M].北京:煤炭工业出版社.

[2] LIU Quanlong,LI Xinchun,GUAN Fuyuan.Research on effectiveness of coal mine safety supervision system reform on three types of collieries in China[J].International Journal of Coal Science & Technology,2014,1(3):376-382.

[3] ZHANG Yanzhong,XIAO Lin.Petrographic characteristics and depositional environment of No.6 coal from Xiaoyugou Mine,Jungar Coalfield,China[J].International Journal of Coal Science & Technology,2014,1(4):395-401.

[4] 赵铁锤.全国煤矿典型水害案例与防治技术[M].徐州:中国矿业大学出版社,2007.

[5] WANG Jinhua.Development and prospect on fully mechanized mining in Chinese coal mines[J].International Journal of Coal Science & Technology,2014,1(3):253-260.

[6] 赵庆彪.高承压水上煤层安全开采指导原则及技术对策[J].煤炭科学技术,2013,41(9):83-86.

ZHAO Qingbiao.Technical countermeasures and guidance principles of seam safety mining above high pressurized water aquifer[J].Coal Science and Technology,2013,41(9):83-86.

[7] 刘守强,武强,曾一凡,等.基于GIS的改进AHP型脆弱性指数法[J].地球科学,2017,42(4):625-633.

LIU Shouqiang,WU Qiang,ZENG Yifan,et al.The improved AHP vulnerable index method based on GIS[J].Earth Science,2017,42(4):625-633.

[8] 董国华,黄欢.运用模糊综合评判法评价煤层底板突水危险性[J].煤炭科技,2016(1):107-110.

DONG Guohua,HUANG Huan.Applying fuzzy comprehensive evaluation method to evaluate the risk of water inrush from coal seam floor[J].Coal Science and Technology Magazine,2016(1):107-110.

[9] 罗斌,齐跃明,白向挺.基于H支持向量机和灰色关联分析突水水源判别[J].煤炭科学技术,2013,41(S2):367-369.

LUO Bin,QI Yueming,BAI Xiangting.Determination of water bursting sources based on H-SVMs and grey correlation analysis[J].Coal Science and Technology,2013,41(S2):367-369.

[10] 武亚遵,杜鹏卓,林云,等.基于分形分维和模糊层次分析的煤层底板突水危险性评价[J].水资源与水工程学报,2017,28(2):156-161.

WU Yazun,DU Pengzhuo,LIN Yun,et al.Risk evaluation of water inrush from coal floor based on fractal dimension and fuzzy hierarchy analysis process[J].Journal of Water Resources and Water Engineering,2017,28(2):156-161.

[11] 陈红江,李夕兵,刘爱华,等.用Fisher判别法确定矿井突水水源[J].中南大学学报(自然科学版),2009,40(4):1114-1120.

CHEN Hongjiang,LI Xibing,LIU Aihua,et al.Identifying of mine water inrush sources by Fisher discriminant analysis method[J].Journal of Central South University(Science and Technology),2009,40(4):1114-1120.

[12] 施龙青,谭希鹏,王娟,等.基于PCA_Fuzzy_PSO_SVC的底板突水危险性评价[J].煤炭学报,2015,40(1):167-171.

SHI Longqing,TAN Xipeng,WANG Juan,et al.Risk assessment of water inrush based on PCA-Fuzzy-PSO-SVC[J].Journal of China Coal Society,2015,40(1):167-171.

[13] 卫贵武.几类模糊多属性决策方法研究[D].西南交通大学,2009.

WEI Guiwu.Study on methods for fuzzy multiple attribute decision making under some situations[D].Southwest Jiaotong University,2009.

[14] 郭凯红,牟有静.基于可能度矩阵的区间型多属性决策方法[J].计算机应用,2012,32(1):218-222.

GUO Kaihong,MU Youjing.Multiple attribute decision-making method with intervals based on possibility degree matrix[J].Journal of Computer Applications,2012,32(1):218-222.

[15] 朱友清,周石琳,邹焕新.基于相容系数的冲突证据合成方法及评价准则[J].系统工程与电子技术,2014,36(6): 1118-1123.

ZHU Youqing,ZHOU Shilin,ZOU Huanxin.Combination method of conflict evidences and evaluation rule based on compatibility ratio[J].Systems Engineering and Electronics,2014,36(6):1118-1123.

[16] 武强,许珂,张维.再论煤层顶板涌(突)水危险性预测评价的“三图-双预测法”[J].煤炭学报,2016,41(6):1341-1347.

WU Qiang,XU Ke,ZHANG Wei.Further research on “three maps-two predictions” method for prediction on coal seam roof water bursting risk[J].Journal of China Coal Society,2016,41(6):1341-1347.