随着低阶煤开采量和采煤机械化程度的增加,低阶煤泥产量和灰分也不断增加。浮选是煤泥分选应用最广泛的技术,对低阶煤泥进行浮选加工,有利于低阶煤的高效清洁利用[1-4]。低阶煤的变质程度低,表面具有较强的亲水性,很难通过常规的浮选手段进行有效地回收[5-6]。现有的低阶煤煤泥浮选,主要通过药剂调节[7-8]、浮选调浆[9-11]、表面改性[12-13]、超声浮选[14-15]等方法调控,提高其可浮性。其中,作为一种结合了多种调控的超声浮选方法,对提高浮选过程的选择性、浮选效率以及浮选效果具有很强的现实意义[16]。

超声浮选是一种将物理调节法和化学调节法相结合的浮选方式,对提高煤泥浮选的选择性和浮选效率效果显著[16]。ÖZKAN等[17]的研究表明超声波预处理可使浮选气泡稳定性增强,浮选速率提高,浮选回收率增加,药剂用量减少。康文泽等[18-19]的研究表明超声波预处理使煤泥接触角、疏水性及矿浆pH增加,润湿热减少,超声浮选的精煤产率、浮选速率、浮选完善度较处理前有明显提高。毛玉强等[20]在低阶煤浮选中引入超声波提高了精煤回收率,降低了精矿灰分,强化了低阶煤的浮选回收。ZHEN Kunkun等[21]研究表明经超声场的浮选搅拌后产生的油滴较小,尤其超声功率较高时。油滴粒径的减小导致了相同柴油用量下油滴总表面积的增加,提高了柴油的利用效率,有利于低阶煤的浮选。普遍认为,超声浮选通过超声空化产生的清洗、侵蚀和乳化作用改变了煤泥表面的物理化学性质,促进了浮选药剂的乳化,从而提高了浮选速率及浮选效果[22]。此外,超声作用于浮选过程,对浮选气泡产生的影响也得到了关注。CHEN Yuran等[23-24]研究了驻波声场对浮选气泡的影响,发现煤颗粒被大气泡聚集和吸引。微浮选试验表明,无论有无超声处理的试验,最终最大回收率相似,但超声聚集作用提高了回收速率。MAO Yuqiang等[25]研究了扩散场对浮选气泡的影响。结果表明:超声使泡沫区的泡沫层厚度变薄,球形气泡的聚集更有利于浮选。JIN Lizhang等[26]研究了不同频率驻波超声对浮选气泡的影响,结果表明,100 kHz的超声场中聚集体和小气泡的数量最多,该条件下得到了最高的精煤产率、可燃体回收率和浮选完善指标。驻波超声促进了气泡与煤粒的聚集,提高了浮选效果。

可见,驻波超声作用于浮选过程中时,不但改变了煤泥表面的物理化学性质,也影响了浮选气泡的行为,2种作用均对浮选结果产生了影响。驻波超声作用的浮选气泡行为对浮选结果的影响较为显著,但相关的机理研究较少。笔者以低阶煤为研究对象,在驻波超声同步柱选装置中进行了柱选试验。在气泡观察装置中,探究了驻波声场中的微泡生成过程、气泡聚集过程和上述过程对浮选选择性的影响。最后,探讨了驻波超声对浮选气泡以及柱选结果的影响。

1 试验部分

1.1 试验煤样

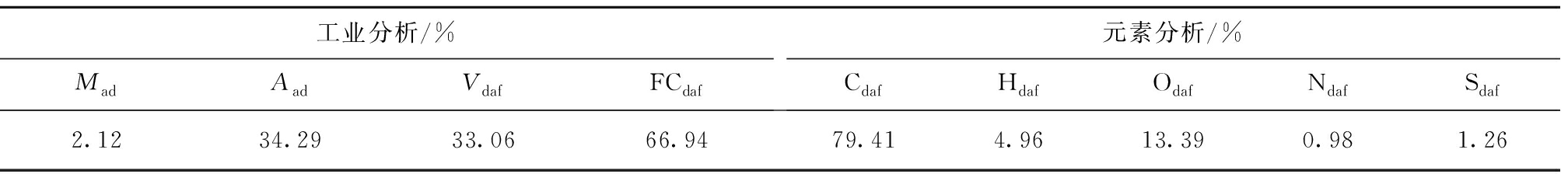

试验煤样为大同矿区四台选煤厂低阶煤煤泥,灰分为34.29%,水分2.12%。煤样粒度分析结果见文献[27],属于高灰细粒煤。表1为煤样的工业分析和元素分析结果。

表1 煤样工业分析与元素分析

Table 1 Proximate analysis and ultimate analysis of coal sample

工业分析/%MadAadVdafFCdaf元素分析/%CdafHdafOdafNdafSdaf2.1234.2933.0666.9479.414.9613.390.981.26

1.2 试验装置

气泡观察装置如图1所示,包括照明装置、观察装置(亚克力制品)、圆形换能器(100 kHz)、超声波发生器(KMD-D2)、高速摄像系统(Q1M 高速摄像系统)。

图1 气泡观察装置

Fig.1 Bubble observation device

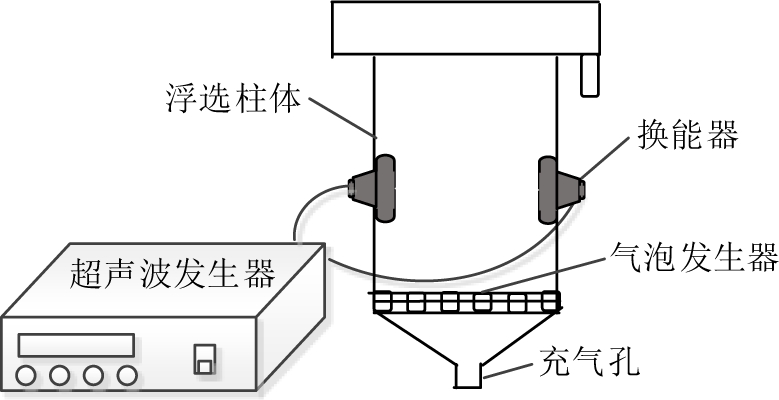

柱选装置如图2所示,在观察装置的基础上,添加了充气孔及气泡发生器,柱选装置不需要照明及高速摄像系统。

图2 超声柱选装置

Fig.2 Ultrasonic flotation column

1.3 试验方法

(1)超声柱选试验方法:称取75 g煤样并润湿,搅拌2 min 后加入捕收剂(煤油)500 g/t,再搅拌1 min后加入起泡剂(仲辛醇)100 g/t,再搅拌30 s制成浮选矿浆(质量浓度50 g/L)。将浮选矿浆转移至柱选装置中,同时开启超声波发生器和充气阀门,泡沫收集5 min。

(2)气泡观察方法:观察室内充满清水,从下方通入空气,观察室中超声场与柱选一致(100 kHz),待充气稳定后,开启超声波发生器和高速摄像系统,记录超声场中的气泡变化情况。微泡产生过程不通入空气。

(3)热解石墨片和云母片:去掉表层后,通过双面胶粘取中间层固定在底板上,在柱选装置中超声处理5 min。

2 结果与讨论

2.1 驻波超声柱选试验结果

驻波超声柱选试验结果见表2。由表2可知,与常规柱选相比,驻波超声柱选的精煤产率、可燃体回收率和浮选完善指标分别达到了21.93%,30.52%和23.77%,柱选结果均得到了提高。精煤灰分为11.13%,比常规柱选低1.07%。

表2 浮选结果

Table 2 Flotation results %

柱选试验精煤产率精煤灰分尾煤产率尾煤灰分可燃体回收率浮选完善指标常规8.8012.2191.2038.5112.119.14超声21.9311.1378.0843.1730.5223.77

本次100 kHz驻波超声柱选试验与驻波超声浮选[27]的区别在于煤样的润湿、搅拌和加药过程没有超声参与,仅在分选过程中加入驻波超声。驻波超声作用于矿浆与气泡的碰撞区。在碰撞区,气泡矿化上浮成为浮选泡沫,该过程在一个较短的时间内完成。因此,在本试验中,驻波超声对煤颗粒的清洗作用和对浮选药剂的乳化作用有限。驻波超声对浮选气泡的强化作用较为突出。

2.2 驻波声场中的气泡行为

图3为加入驻波声场后气泡观察装置中的气泡聚集过程,即在800 ms内驻波声场中气泡聚集体的形成及分布过程。气泡聚集体在未加超声时未出现,400 ms时的分布状态已经较为明显,至800 ms时的分布状态已完全稳定且清晰。无超声时,气泡在整个观察装置内均匀分散;当加入驻波超声时,气泡有规律地聚集,形成不同形状和大小的气泡聚集体;趋于稳定后,气泡聚集体更明显,以条纹状聚集态分布在整个驻波声场中。与扩散声场对浮选过程的搅拌、乳化和减小气泡尺寸等作用[22]相比,上述气泡聚集现象是驻波声场最明显的特性[28]。

图3 气泡聚集过程

Fig.3 Bubble aggregation process

图4为气泡观察装置中一个气泡聚集体的形成过程。在间隔25 ms、共75 ms的过程中,驻波声场中的气泡由松散态到聚集态,形成“包裹团”或“链状”的气泡聚集体。在聚集体的形成过程中,聚集时间较短,气泡在声场驱动下的运动行为能够促进煤颗粒和气泡的碰撞[29],使矿化过程更易发生。

图4 气泡聚集体的形成过程

Fig.4 Formation process of bubble aggregates

气泡聚集体的生成原理即驻波使气泡在波的叠加处聚集。在声场作用下的气泡会发生体积脉动。如果声压梯度不为0,它可以与气泡振荡耦合,从而在气泡上产生一个驱动力,即Bjerknes力。Bjerknes力是非流动液体中气泡运动的最有力的驱动力。由于声场的作用,小于共振尺寸的气泡沿声压梯度上升,而大于共振尺寸的气泡沿声压梯度方向移动。因此,在驻波声场中,前者在波腹处聚集,后者在波节处聚集[30]。

如图5所示,在观察气泡聚集体的形成过程中加入试验煤样,形成了有“包裹团”和“链状”的煤-气泡聚集体。该试验结果表明,驻波声场中的气泡聚集过程对矿化气泡同样产生作用。“链状”的煤-气泡聚集体,将矿化气泡连接在一起,而“包裹团”的存在,可能将矿浆包裹在其中导致选择性较差[31]。图中也可以看出,“包裹团”的数量少于“链状”的煤-泡聚集体数量。因此,驻波声场中生成了煤-气泡聚集体,得到了较好的柱选结果。

图5 煤-气泡聚集体

Fig.5 Coal-bubble aggregates

2.3 驻波声场中微泡的产生及其作用

如图6所示,在静水中加入驻波声场10 s,产生了可见的微米级气泡(小于300 μm)。这些微泡泡可以附着在气泡聚集体上,如图7所示。驻波声场在浮选过程中的作用除了提供能量和促进气泡聚集外,还有生成微泡的作用。在驻波声场中,微泡的产生与超声空化及气体析出有关。声场中的声波在液体中传播时改变了液体内部静压,形成了负压区和正压区。液体中的空腔结构在负压区生长,在正压区压缩,反复的正负压生长过程导致该结构破裂为更小的气泡,破裂过程同时产生能量和微射流,这种现象被称为超声空化[32-33]。声波在液体中的传播也会导致溶解在液体中气体析出形成微泡[34-35]。驻波超声产生的声场驱动力能够促进气泡矿化,该气泡为微泡时矿化过程更易发生[29]。

图6 微泡产生过程

Fig.6 Generation process of microbubble

图7 附着微泡的气泡聚集体

Fig.7 Aggregation of bubbles with microbubble

2.4 驻波声场中微泡附着的选择性

如图8所示,将表面粗糙度相近的热解石墨片(平均粗糙度为388 pm)和云母片(平均粗糙度为240.7 pm)在柱选装置中超声5 min后,热解石墨表面附着大量微泡和少部分大气泡。大气泡的周围存在气泡“消失”区域,因此可以判断,大气泡是由微泡聚集兼并[36]产生,大气泡上同样附着部分微泡,这与图7试验结果一致。云母片超声5 min未见明显变化。

图8 驻波超声处理后的样品表面

Fig.8 Sample surface with ultrasonic treatment

驻波声场中产生的微泡有选择性地附着在疏水表面,进一步提高其疏水性,同时,距离相近的微泡易发生兼并行为,生成较大的气泡。当微泡作为“介质”参与煤-泡聚集体的形成过程时,该聚集过程具有了一定选择性。相比于单个气泡,煤-泡聚集体能浮出更多精煤。因此,与常规柱选相比,驻波超声柱选的精煤产率、可燃体回收率和浮选完善指标均有所提高。

3 结 论

(1)驻波超声加入柱选后,可以强化低阶煤煤泥柱选效果。精煤产率、可燃体回收率和浮选完善指标分别达到了21.93%,30.52%和23.77%,均高于常规柱选;精煤灰分为11.13%,比常规柱选低1.07%。

(2)进入驻波声场的气泡有规律地聚集,形成不同形状和大小的聚集体,在趋于稳定后,聚集体以条纹状聚集态分布在整个驻波声场中。与扩散声场对浮选过程的搅拌、乳化和减小气泡尺寸等作用相比,气泡聚集是驻波声场最明显的特性。

(3)驻波声场在整个柱选过程中的作用为提供能量、促进聚集和产生微泡。声场驱动力提供了能量,促进了煤颗粒与气泡之间的碰撞。在声驱动力的作用下,气泡以条纹状聚集态分布在整个驻波声场中。微泡作为煤颗粒和大气泡之间的“介质”,可在很短的时间内促进其聚并,形成煤-泡聚集体,且该过程具有一定选择性。这些煤-气泡聚集体在浮选过程中进入泡沫层,最终成为浮选精煤。提高了精煤产率、可燃体回收率和浮选完善指标,降低了精煤灰分。

[1] 侯诗宇,马力强,黄根,等.不同密度细粒煤泥对粗粒煤泥浮选的影响机理[J].煤炭学报,2016,41(7):1813-1819.

HOU Shiyu,MA Liqiang,HUANG Gen,et al.Mechanism of the effect of fine coal with different densities on coarse coal flotation[J].Journal of China Coal Society,2016,41(7):1813-1819.

[2] 谢广元,倪超,张明,等.改善高浓度煤泥水浮选效果的组合柱浮选工艺[J].煤炭学报,2014,39(5):947-953.

XIE Guangyuan,NI Chao,ZHANG Ming,et al.Enhanced separation of high concentration coal slurry by a two stages process with different flotation columns[J].Journal of China Coal Society,2014,39(5):947-953.

[3] ZHU Chunyun,XING Yaowen,XIA Yangchao,et al.Flotation intensification of low-rank coal using a new compound collector[J].Powder Technology,2020,370:197-205.

[4] SUN Wei,HU Yuehua,DAI Jingping,et al.Observation of fine particle aggregating behavior induced by high intensity conditioning using high speed CCD[J].Transactions of Nonferrous Metals Society of China,2006,16(1):198-202.

[5] 王永刚,周剑林,林雄超.低阶煤含氧官能团赋存状态及其对表面性质的影响[J].煤炭科学技术,2013,41(9):182-184,187.

WANG Yonggang,ZHOU Jianlin,LIN Xiongchao.Deposit conditions of oxygen functional groups in low rank coal and affected to surface properties[J].Coal Science and Technology,2013,41(9):182-184,187.

[6] 王市委,陈松降,陶秀祥,等.低阶煤颗粒-气/油泡间的疏水力常数研究[J].煤炭学报,2019,44(7):2236-2244.

WANG Shiwei,CHEN Songjiang,TAO Xiuxiang,et al.Investigation of hydrophobicity constants between air/oily bubbles and low-rank coal particles[J].Journal of China Coal Society,2019,44(7):2236-2244.

[7] XU Mengdi,XING Yaowen,CAO Yijun,et al.Waste colza oil used as renewable collector for low rank coal flotation[J].Powder Technology,2018,344:611-616.

[8] XIA Wencheng,YANG Jianguo,LIANG Chuan.Improving oxidized coal flotation using biodiesel as a collector[J].International Journal of Coal Preparation and Utilization,2013,33:181-187.

[9] 马力强,韦鲁滨,江兴华,等.调浆剪切强度对煤泥浮选的影响[J].煤炭学报,2013,38(1):140-144.

MA Liqiang,WEI Lubin,JIANG Xinghua,et al.Effects of shearing strength in slurry conditioning on coal slime flotation[J].Journal of China Coal Society,2013,38(1):140-144.

[10] XU Mengdi,XING Yaowen,GUI Xiahui,et al.Effect of ultrasonic pre-treatment on oxidized coal flotation[J].Energy & Fuels,2017,31(12):14367-14373.

[11] MAO Yuqiang,XIE Guangyuan,QI Xuhui,et al.Effects of ultrasonic pretreatment on particle size and surface topography of lignite and its relationship to flotation response[J].Energy Sources,Part A:Recovery,Utilization,and Environmental Effects,2021,43(10):1274-1282.

[12] SOBHY A,TAO D.Nanobubble column flotation of fine coal particles and associated fundamentals[J].International Journal of Mineral Processing,2013,124(6):109-116.

[13] NIU Chenkai,XIA Wencheng,XIE Guangyuan.Effect of low-temperature pyrolysis on surface properties of sub-bituminous coal sample and its relationship to flotation response[J].Fuel,2017,208(15):469-475.

[14] KOPPARTHI Prasad,BALAMURUGAN S,MUKHERJEE A K.Effect of ultrasonic pre-treatment time on coal flotation[J].International Journal of Coal Preparation and Utilization,2020,40(12):807-823.

[15] 康文泽,荀海鑫,李明明.超声波预处理对稀缺难浮煤浮选的作用[J].中国矿业大学学报,2013,42(4):625-630.

KANG Wenze,XUN Haixin,LI Mingming.The effect ultasonic pretreatment on the flotation of scarce difficult-to-float coals[J].Journal of China University of Mining & Technology,2013,42(4):625-630.

[16] 康文泽,胡军.物理调节法对矿物浮选的影响[J].洁净煤技术,2004,10(4):21-23.

KANG Wenze,HU Jun.Effect of physical adjustment method on mineral flotation[J].Clean Coal Technology,2004,10(4):21-23.

[17] OZKAN Safak G,KUYUMCU Halit Z.Investigation of mechanism of ultrasound on coal flotation[J].International Journal of Mineral Processing,2006,81(3):201-203.

[18] 康文泽,丁淑芳,胡军.超声波对煤泥浮选的影响[J].黑龙江科技大学学报,2010,20(3):183-188.

KANG Wenze,DING Shufang,HU Jun.Effect of ultrasonic treatment on slime flotation[J].Journal of HeiLongjiang Institute of Science & Technology,2010,20(3):183-188.

[19] 康文泽,王慧,陈俊涛,等.煤泥超声浮选的试验研究[J].洁净煤技术,2005,11(3):35-37.

KANG Wenze,WANG Hui,CHEN Juntao,et al.Expermiental study of slmie ultrasonic flotation[J].Clean Coal Technology,2005,11(3):35-37.

[20] 毛玉强,夏文成,卜祥宁,等.超声波强化褐煤浮选及其作用机制探讨[J].煤炭学报,2017,42(11):3006-3013.

MAO Yuqiang,XIA Wencheng,BU Xiangning,et al.Discussion on ultrasonic enhanced lignite flotation and its action mechanism[J].Journal of China Coal Society,2017,42(11):3006-3013.

[21] ZHEN Kunkun,LI Xin,ZHANG Chunquan,et al.The flotation intensifying of low-rank coal based on the ultrasonic field[J].Energy Sources,Part A:Recovery,Utilization,and Environmental Effects,2020(10):1762-1771.

[22] WANG Weidong,LIU Dinghua,TU Yanan,et al.Enrichment of residual carbon in entrained-flow gasification coal fine slag by ultrasonic flotation[J].Fuel,2020,278:118-195.

[23] CHEN Yuran,NI Chao,XIE Guangyuan,et al.Toward efficient interactions of bubbles and coal particles induced by stable cavitation bubbles under 600 kHz ultrasonic standing waves[J].Ultrasonics Sonochemistry,2020,64:105003.

[24] CHEN Yuran,TRUONG Vu N T,BU Xiangning,et al.A review of effects and applications of ultrasound in mineral flotation[J].Ultrasonics Sonochemistry,2020,60:104739.

[25] MAO Yuqiang,CHEN Yuran,BU Xiangning,et al.Effects of 20 kHz ultrasound on coal flotation:The roles of cavitation and acoustic radiation force[J].Fuel,2019,256(15):115938.1-115938.7.

[26] JIN Lizhang,WANG Weidong,TU Yanan,et al.Effect of ultrasonic standing waves on flotation bubbles.[J].Ultrasonics Sonochemistry,2021,73:105459.

[27] 王卫东,靳立章.细粒煤超声同步浮选的试验研究[J].煤炭学报,2020,45(8):2949-2955.

WANG Weidong,JIN Lizhang.Study on ultrasonic simultaneous flotation of coal fines[J].Journal of China Coal Society,2020,45(8):2949-2955.

[28] CHEN Yuran,XIE Guangyuan,CHANG Jing,et al.A study of coal aggregation by standing-wave ultrasound[J].Fuel,2019,248:38-46.

[29] NGUYEN Anh V,RALSTON John,SCHULZE Hans J.On modelling of bubble-particle attachment probability in flotation[J].International Journal of Mineral Processing,1998,53(4):225-249.

[30] MAKSIMOV A O,LEIGHTON T G.Acoustic radiation force on a parametrically distorted bubble[J].Journal of the Acoustical Society of America,2018,143(1):296-305.

[31] WANG Bo,PENG Yongjun.The behaviour of mineral matter in fine coal flotation using saline water[J].Fuel,2013,109(7):309-315.

[32] KANG Wenze,XUN Haixin,TAO Chenjun.Study of enhanced fine coal de-sulphurization and de-ashing by ultrasonic flotation[J].Journal of China University of Mining & Technology,2007(3):62-66.

[33] SUSLICK K S,DOKTYCZ S J,FLINT E B.On the origin of sonoluminescence and sonochemistry[J].Ultrasonics,1990,28(5):280-290.

[34] 郭梦熊,曾凡,田秀兰.超声强化浮选过程的机理[J].中国矿业大学学报,1980(1):46-53.

GUO Mengxiong,ZENG Fan,TIAN Xiulan.The mechanism of coal flotation forced by ultrasound[J].Journal of China University of Mining & Technology,1980(1):46-53.

[35] ZIJLSTRA A,RIVAS D F,GARDENIERS H,et al.Enhancing acoustic cavitation using artificial crevice bubbles[J].Ultrasonics,2015,56:512-523.

[36] ZHANG Lijuan,ZHANG Xuehua,ZHANG Yi,et al.The length scales for stable gas nanobubbles at liquid/solid surfaces[J].Soft Matter,2010,18(6):4515.